Autodesk Tandem: digital twin update

Autodesk Tandem launched in 2o21, a cloud-based digital twin platform. While very much a work in progress, the launch offered some insight into the direction Autodesk is taking, as well as what might be achieved in future, using Forge components. Martyn Day reports on forthcoming capabilities

A journey of a thousand miles begins with a single step. In keeping with that maxim, the 2021 launch version of Autodesk’s cloud-based digital twin platform Autodesk Tandem showcased only a fraction of the capabilities that might eventually be expected on the company’s journey to flesh out the product.

Autodesk started where it needed to start, working predominantly with Revit data, to come up with a platform capable of supporting the rapid display and filtering of Revit BIM data.

To do this, the team created a new parallel file format, removing unnecessary and heavier elements of Revit data not required in downstream maintenance and facilities management. This decision immediately delivered a side benefit of making Autodesk Tandem a great Revit model viewing tool.

Since then, more has been made clear. Ahead of the 2022 Autodesk University event, the Tandem team held a public Zoom call for interested parties who wanted to see the capabilities it plans to deliver. While vanilla in functionality, the demonstration of this initial offering made it clear that Autodesk is aiming to put a lot more ‘meat on the bones’ in the year ahead.

In particular, Autodesk developer Kean Walmsley’s Project Dasher work on sensor technology and 3D rendering techniques ranks high on the list of potential forthcoming features. (This is a development I pondered in an earlier article on Tandem.) However, I should point out that according to Autodesk’s Safe Harbor statement, displayed immediately before the start of the Tandem session on Zoom, features demonstrated may or may not appear in the shipped product.

Opening remarks

The session opened with an explanation by Bob Bray, VP & general manager, Autodesk Tandem, of the company’s long-term aims for the product and the role it sees digital twins playing in the AEC process.

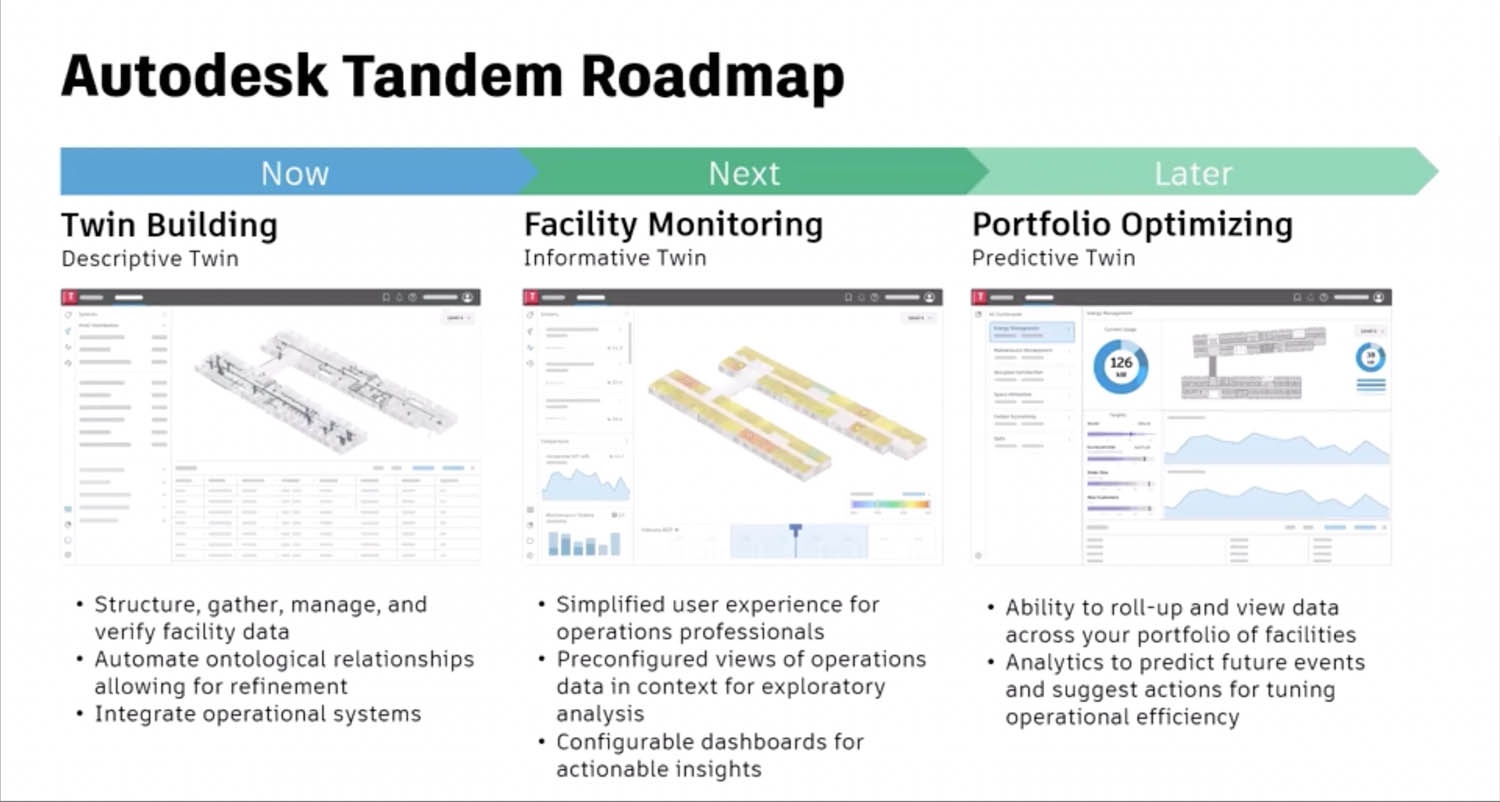

“We really think about how we help our AEC customers [of] today become the digital twin providers of tomorrow. And that’s through this notion of digital handover,” he said. “How do we harness the process that we all use today in terms of delivering projects, to really create that digital twin, with all of those connections to operational systems and data, intact at handover? He continued: “We think about the initial twin as being a descriptive twin. What are the spaces? What are the equipment, the assets in that facility? How are those things connected together into systems to create that replica of the building?”

Autodesk aims to show operational information in the context of that digital twin and start to draw some insights from connected assets, pieces and systems, as well as live operational data, said Bray.

“Then [we want to move] downstream into the ability to take that collected data and create predictive insights, like when might this component fail, based on past history of similar components in my portfolio of facilities, and then moving on to run simulation of a comprehensive twin and eventually the idea of a twin that can self-tune and self-heal the building.”

Building tools

This being Autodesk, no product would be complete without some way to encourage third-party developers to build on top of the base solution — and that requires robust APIs (application programming interfaces) and SDKs (software development kits). With Auodesk Tandem being a cloud-based application, web APIs will be essential to connect and extend Autodesk’s digital twin offering.

Bray outlined Autodesk’s API / SDK approach as follows: “The Tandem platform is built on Autodesk Forge. This starts with this idea of a low-level API that provides access to all the asset information, access to any of the event history and time-series data that’s being collected. Then a slightly higher-level SDK is built around the ability to create a custom digital twin that wraps around that, if that’s the desired effect.”

With Tandem being a cloud-based application, web APIs will be essential to connect and extend Autodesk’s digital twin offering

Bray went on to state that Autodesk envisages building a long-term marketplace of vertical integrations to various content management systems (CMSs), integrated database management systems (IDMSs) and other types of operational solutions, as well as custom data analytics. Ideally, these would be simple plugins that could be repurposed across multiple sites and multiple tools, without needing a lot of new coding and reducing the cost of development and operation.

Internet of Things (IoT)

New features in development were demonstrated using a digital twin of Autodesk’s downtown Toronto office, which is fitted with IoT sensors and a building management system (BMS), modelled in Revit, and then connected to a live Tandem representation.

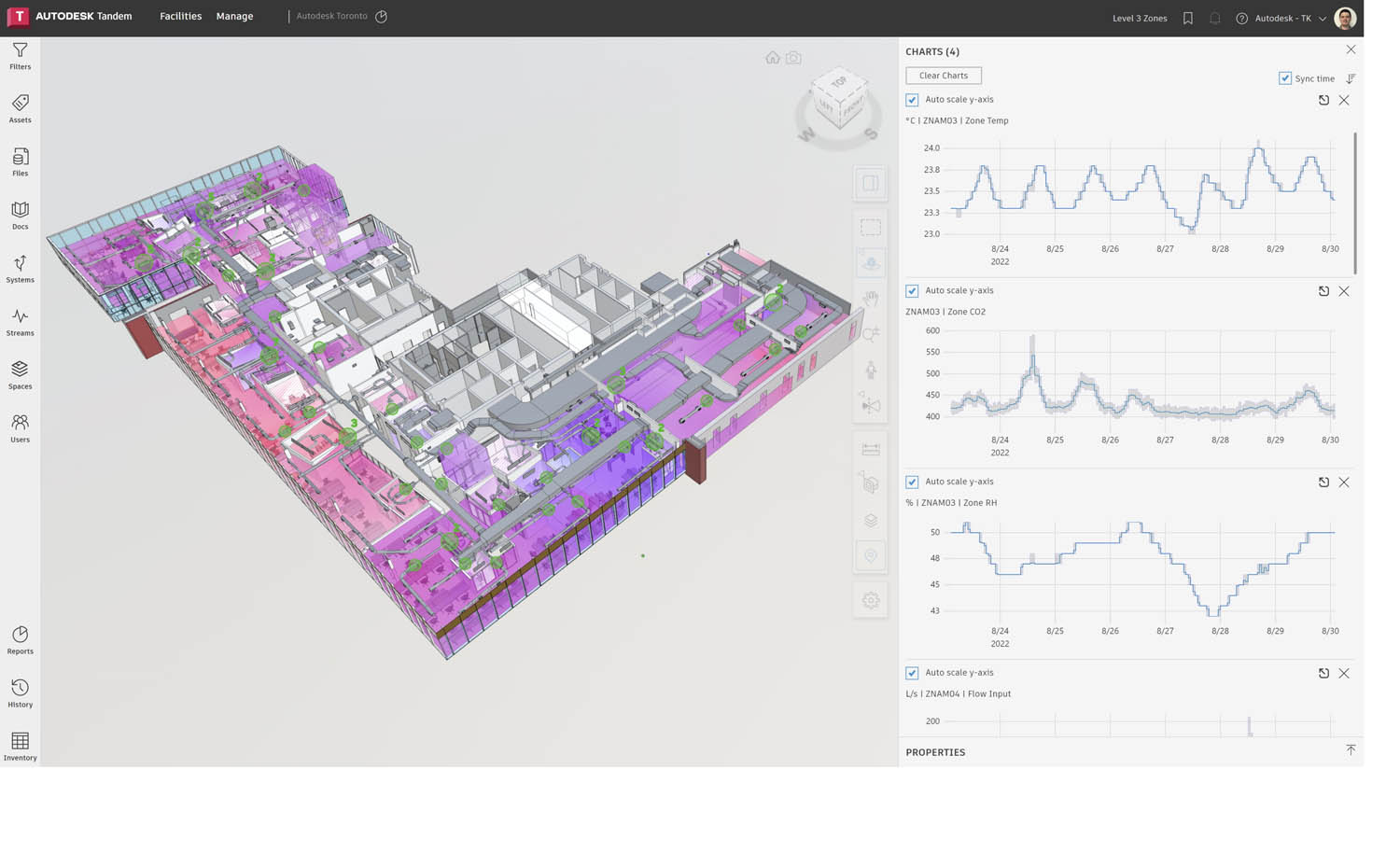

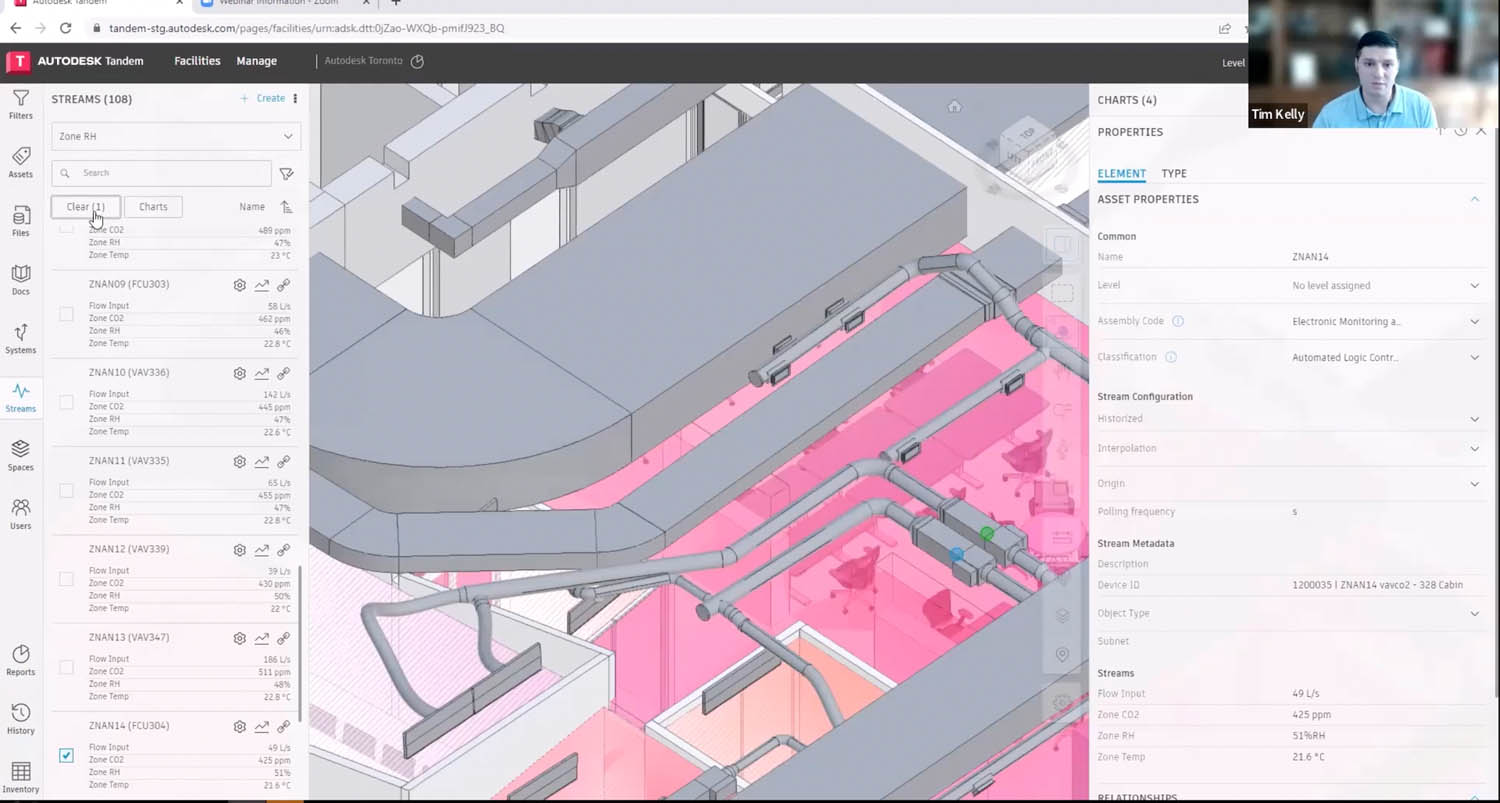

The session showed how it is possible to interrogate the BMS and see flow rates, CO2 levels and humidity across 90 zones over multiple floors and various MEP systems. These connections can be achieved via individual or batch collection, or from IoT hub import from Microsoft Azure.

Using a template structure, the capture data can be easily defined, tagged, mapped and reformatted. This is essential, since IoT and BMS implementations differ widely in how they package up and format data and because consistency of data is paramount. While you can see snapshot data in the streams panel, it’s also possible to see charts for individual devices over time and drill down deeper into the underlying data.

Numbers and graphs are great for specifics, but a new feature in development supports 3D coloured heat maps across entire floors. This is achieved by allocating units and sensors to individual spaces and zones, enabling these heat maps to display temperature, humidity, CO2 levels and so on. This makes it easy for building managers to identify problem areas and drill down into the information to predict potential hardware failures. In the future, Autodesk sees this data forming the basis of an alert system. Spaces and workspaces Tandem organises data into four categories: assets, spaces, systems and streams.

Assets are individual items, such as a chair. A system would be MEP, for example. Streams are inputs from a building’s sensors and management systems.

But when is a space a space? It’s important to be able to slice and dice and navigate areas of a building and collate equipment and sensors together. Here, Tandem relies heavily on Revit’s concept of spaces when importing the BIM model. But when defining a room, you will have transitional MEP elements, façade elements and other systems running through them.

Post import, it’s possible to define groups of assets, elements, devices and transitional elements as they belonging to a specific space; these could be floors or rooms, for example. Once these are defined, navigation throughout the building can be fast. Tandem also offers fast floorplan generation showing the space allocation.

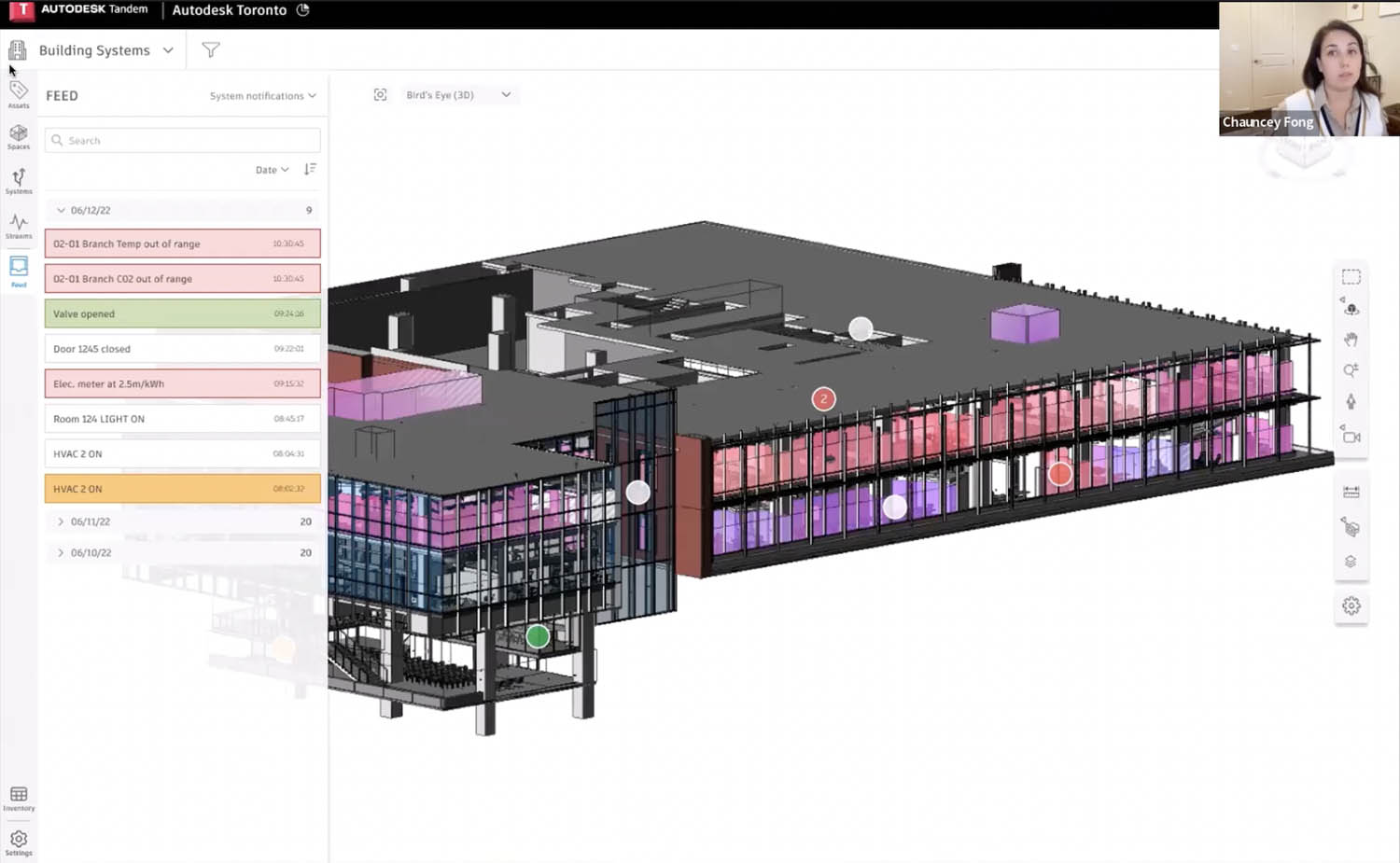

Workspaces are a toggleable prototype capability that offer unique configurations to address the individual needs of specific users with role / permission access controllable by a site admin. We were given two examples: a digital twin handover (digital twin builders) and facility monitoring (systems and sensor data monitoring).

In the data validation workspace, the user is building the digital twin in Tandem. They can see all sources of data being imported to the workspace, the version history and the time data was updated. Also, Workspaces show the classifications that can be allocated to imported objects (assets, spaces, systems, streams), together with a colour coded progress system to indicate how much more work is needed to apply digital twin mapping to the imported geometry. There are an array of filters that enable the user to quickly see what remains to be defined / tagged.

Within the Operate category, we saw the facility monitoring workspace. This shows the digital twin with all event data from IoT sensors and highlighting notifications, which automatically alert the user when sensors report findings that fall outside of predefined parameters. Tandem can then show the sensors in the model that are out of range, enabling operations teams to drill down deeper into problems.

Autodesk Tandem is still very Revit focused, but to be fair, RVT is the market-leading format for BIM data in many regions

Workspaces appears to be the way Autodesk is approaching the various roles that fall within Computer Aided Facility Management (CAFM). There are unique workspaces for common job roles, for example, and this approach ensures that data is managed by an admin, while users are provided with just the functionality and level of detail that is appropriate to their responsibilities. I am sure there will be many additional Workspaces to come.

Portfolio concepts

Autodesk is also looking at how Tandem handles multiple buildings, as well as multiple campuses in different regions and countries. To facilitate this, the team is developing new interfaces and navigation front-ends for multi-building and international clients. Here, customers should ensure that they have good internal standards that govern how every building in a portfolio is managed, ensuring that the same quality metrics are applied and that data mapping is supported across multiple facilities. Autodesk is developing templates for this.

Conclusion

The updates scheduled for Tandem represent a significant leap forward from what was available in the initial release of this product. Tandem is still very Revit-focused, but to be fair, RVT is the market-leading format for BIM data in many regions.

It’s also clear that Autodesk is working to make digital twins and dashboarding a lot less complex, through the delivery of a plug-and-play system of components, in an area where projects have previously relied heavily on a great deal of custom programming and bootstrapping. While implementations may still require some tailoring, a configurable system is still easier and cheaper to deploy than a custom made digital twin created from scratch.

The colour mapping feedback of buildings is simple but compelling, offering easy to interpret information, and alert/ notification capabilities from sensors and spaces will help back up alerts with extra detail.

One year on from launch, the team is now tackling a number of complex issues that take the Tandem platform way beyond its core definition. There is still a lot of work to be done, and many other data types to be considered — but what Tandem does today, it does well.

Main image: Colour-coding to show which elements still need classifying

The post Autodesk Tandem: digital twin update appeared first on AEC Magazine.

Powered by WPeMatico